Spaceman riding a rocket - desk lamp

Hey guys.

So, think about this: the birthday of one good friend it's close by and you have to find a cool, original idea to make a present and that present should not be bought from China (if it's on a chinese website, it's not original for sure 😆).

Having a 3D printer and a small CNC machine at home, makes the job easier, but the most important aspect of manufacturing something cool, it's the idea.

Our friend is a geek, passionate about space stuff and everything SF related, so the google search tags for an idea were like "rocket","astronaut","space".

After a bit of research I've found this nice SVG kit on Etsy , purchased it and started the design in Fusion360.

The idea was to make a desk lamp that has an astronaut riding a rocket engraved by the 3018CNC on a Polycarbonate(PC) sheet, then make a contour cutting by the same machine.

This was my first serious CNC challenge since I've started playing with the CNC machine, this year, so bare with me.

At first I've cut a PC sheet with the dimensions close to what I've set in Manufacturing side of Fusion360. Then, I've mounted the sheet on the machine's working table using double sided sticky tape, because using nuts and bolts can induce a bowing effect on the whole material and that's so not good.

For the origin, I've set up the bigger circle underneath the rocket. That point was used for calibrating the starting position of the engraving bit, then for calibrating the starting position for the cutting bit. At the end of the contour cutting process, that circle was removed as a disk from the inside of the finished work, so no traces can be found about the origin. Neat, huh? 😎

The cutting process performed flawless, using the feed values in the picture below and Depth of Cut used was 0.25mm.

After CNC job was finished, the post-processing of the polycarbonate thing consisted in sanding of the bottom edge which got inserted into the base. A fine grit sandpaper was used in order to make the surface almost transparent, to make the light pass more easily into the material.

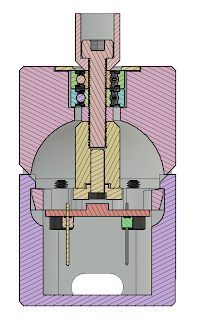

For the base, at first I've thought about making it from hard wood on the CNC, making some pockets inside for the LED strip and an aluminum plate, but after some tries, the 3018CNC was unable to perform the task in a proper manner, without any proper upgrades, that are going to be presented in other post.

Being unable to make a wooden base for the lamp, I've designed the base to be 3D printed. And it was so cool to see how awesome it got after printing.

For post processing for the base, I've used few layers of primer and then few layers of concrete like spray paint to make it look like a stone or brick.

After few coatings of spray paint, I realized that I didn't considered the tolerance changes after applying the paint. Next time, I'll try to fix that. 😅

The polycarbonate part was fixed in place into the corresponding slot on the base using 2 component adhesive.

Next up, for the lighting, I've used a LED strip with batteries from Pepco and I've cut it to length.

Because the spacing between LEDs were higher than my expectations for this project, I've bended the band in such manner to have the LEDs closer.

Also, because LEDs tend to get warmer when on, I've stuck the strip on an aluminum band cut to fit the slot made in the 3D printed base. After soldering the wires, the band was bolted with 2 M3 countersunk screws.

At the end, I've bolted the 3D printed cover, with the same type of M3 screws to hide the aluminum band and that's all. 😏